Membrane Air Spring Isolators

Membrane Air Spring Isolators Manufacturer in India

Unick Vibration is the leading Membrane Air Spring Isolators Manufacturer in India. We provide high-quality, technologically advanced vibration control solutions designed for both industrial machines and precision laboratory equipment.

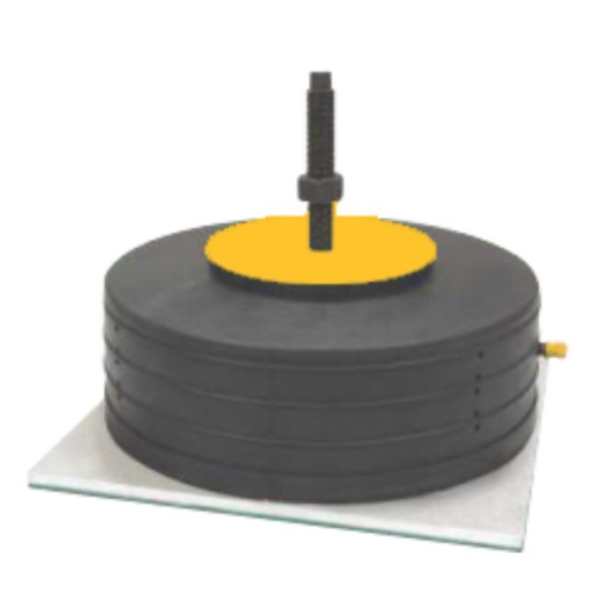

The Unick Membrane Air Spring Isolator is constructed in a cast aluminum body. It consists of an air chamber that is sealed with a reinforced, flexible diaphragm. When compressed air is inserted through the inlet valve, the isolator supports its payload using a piston which is located on the top of the diaphragm. We can calculate the load capacity of the isolator by using the pressure on the diaphragm and the effective area of the diaphragm. The permissible Temperature Range is -20deg C to +90 deg C.

The typical pneumatic isolator design incorporates dual air chambers. It has a very low-level natural frequency. It can be removed the vibration frequency below 2 Hz.

Applications of Membrane Air Spring Isolators

- Coordinate Measuring Machines (CMM)

- Metrology Inspection Devices.

- Electronic Microscope.

- Spectrometers.

- Roughness Tester.

- Hardness Tester.

- Analytical Balance.

- Atomic Absorption Spectrophotometers.

- Roundness Tester.

- Microscope.

- Galvanometer.

- Atomic Force Microscope.

- Profile Projectors etc.

Exercise:

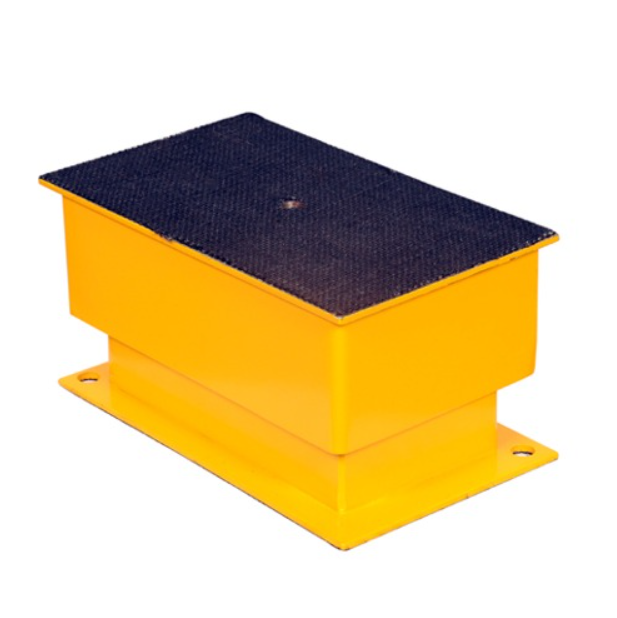

In case of Sensitive Equipments like Coordinate Measuring Machine (CMM), We can achieve highly effective vibration isolation by using “Cradles” or “Custom designed Rigid Frames”. Cradles increase the stability of self levelling pneumatic isolation system by lowering the center of gravity. A cradle support frame is used to position the membrane air spring isolators achieve the reduction in passive vibration. Second, it is also used when a machine base cannot be modified to place the isolators and then rigid frame is required.

Contact Us

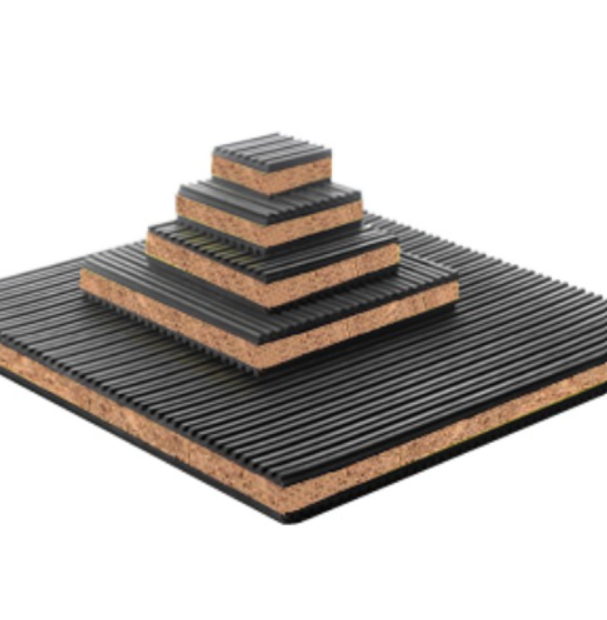

High-Efficiency Membrane Air Spring Isolators

Experience top-tier vibration reduction with modern membrane-based isolation systems.