VMC (Vertical Machining Centre) machines are the essential pillar of manufacturing activity in most of the Haryana workshops. The winning point of a workshop is the combination of precision, speed, and durability, and the quality of the output is affected by every little detail. Therefore, now more than ever, machine stability and vibration control are crucial. Unick Insulation Sheets come in as a revolutionary product that promises not just to facilitate the performance enhancement, but also to give a decrease in vibration, and to give to the protection of the expensive machinery.

Through this article, you will learn about the phenomenal impact the Unick Insulation Sheets have on the VMC operations and the reasons for so many workshops in Haryana to depend on them for better quality of work.

How Unick Insulation Sheets Enhance VMC Machine Stability and Productivity

Each VMC machine is a source of heat and vibration during the process of operation. Gradually, these two forces lead to the mechanical stress, the precision loss, and the production cycles being drawn out. This is exactly the reason for which it is suggested that the use of the Unick Insulation Sheets should be installed, in order to bring about a significant difference.

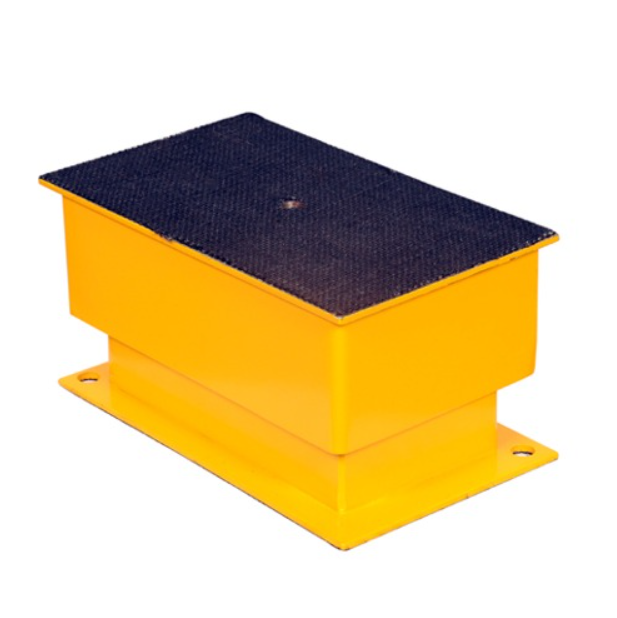

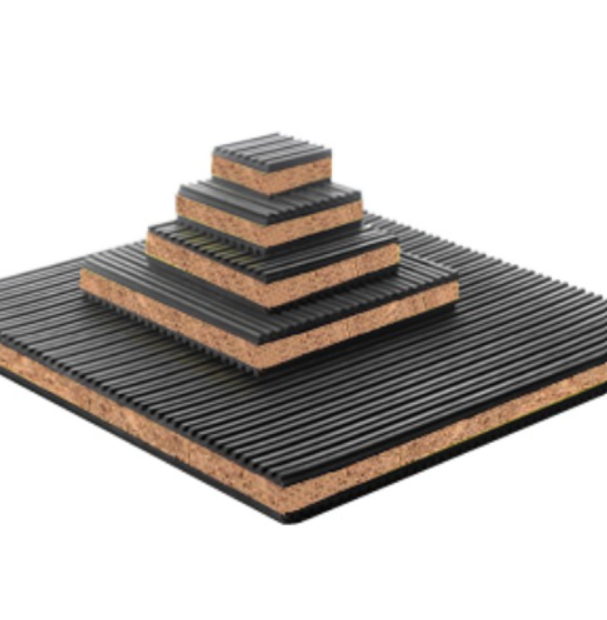

The Unick Insulation Sheets, created by Unick Vibration Solutions, serve as a physical and thermal barrier under the hulk VMC machines. Besides that, they are doing the job of vibrations absorption and eliminating the micro-movements responsible for misalignments. The outcome of these actions is that machining is becoming smoother, surface finishes are becoming consistent, and cutting performance is precise throughout the long production runs.

This is how Unick Insulation Sheets are adding value to the daily operations:

- Reduced Vibrations: The product of the sheets is that they are materially lessening the vibrations coming from the floor, which means that the spindle and the cutting tools are always in the best alignment.

- Better Work Accuracy: The very stable footing of the machine results in no or very little tool deviation and consequently fewer dimensional errors.

- Lower Noise Levels: The noise level is reduced to such an extent that operators would not feel tired and the overall working condition would be more pleasant and comfortable.

- Improved Productivity: The machines are able to work at their best performance without any risk of overload or overheating.

- Lower Current Leakage: The insulation is designed to reduce electric current leakage to a minimum and thus help in eliminating slipping that might happen near the machinery.

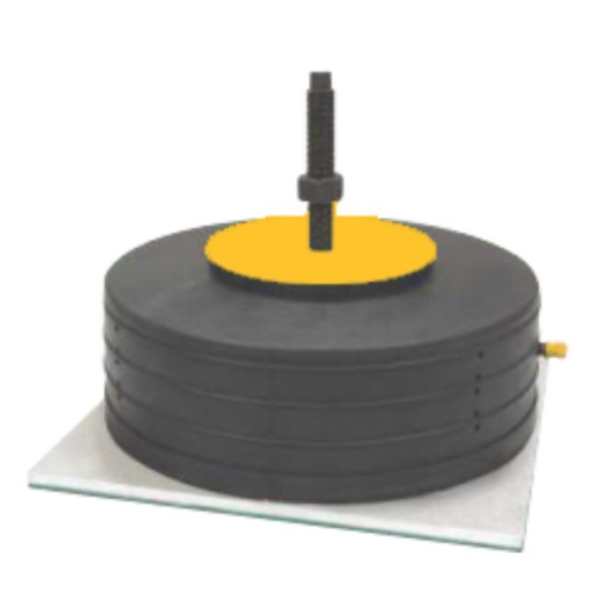

In addition for Heavy Duty Anti Vibration Pads, Unick Insulation Sheets have a positive impact on the lifespan of the VMC foundation and important parts since they have less application of stress on the joints, bearings, and mounting points.

Why Haryana’s VMC Workshops Prefer Premium-Grade Insulation for Long-Term Efficiency

Haryana’s industrial zones, especially in Sonipat and Kundli, are not only great for the manufacture of automotive parts but also plastics, moulds and precision engineering. Quality has always been the main criterion for workshop owners, and thus investing in vibration isolation of premium grade is considered to be a necessity in operational terms rather than direct cost.

On the other hand, when it comes to dependability, Unick Insulation Sheets have been able to make a good name for themselves by offering nothing but consistent performance. The key ingredient in making those sheets or using dense elastomeric compounds and reinforced designs is that they cater to the heaviest VMC bases.

Some of the main factors why workshops in Haryana favour Unick insulation are as follows:

- Ability to withstand high load with long-lasting effectiveness.

- Suitability for all types of floors, including concrete and steel-plate.

- Resistance to exposure to oil, heat, and water.

- Almost no maintenance needed.

- CNC, VMC, and SPM equipment adoption already in place.

Thus, a lot of VMC machine owners experience a decrease in reworks, a reduction in downtime, and an increase in energy efficiency after the installation of Unick Sheets.

The Role of Unick Vibration Solutions in Reducing Downtime and Machine Wear

Downtime does not only cost but also the machine industry in Haryana is so competitive that the one who has the most productivity will always win. Unick Vibration company understands this difficulty and helps the customers with state-of-the-art insulation and damping materials.

Unick Insulation Sheets and Anti Vibration Cushy Foot are not only made from generic rubber or ordinary foam but they are specially designed based on thorough analysis of vibrations and loading. The manufacturer utilizes its knowledge in controlling dynamic vibrations and in doing so provide insulation sheets for use in industry.

And this leads to:

- Vibration reduction impact on the floor retraction.

- Keeping of parts more precise less time.

- Foundations with no crack or distortion are the ones that live the longest.

- Cutting precision stays the same even in the case of the hardest operations going on continually.

In other words, every hour not spent on maintenance or downtime is directly converted into higher returns, and that is exactly what Unick solutions offer.

Top Benefits of Using High-Density Insulation Sheets in CNC & VMC Operations

For machine owners who want the best of both worlds, Unick’s insulation sheets of high density offer a significant advantage. They incorporate many benefits that exceed the need for noise control.

Such benefits are:

- Thermal Protection: Keeps the machine at the desired temperature throughout the long operating cycles, thus directly improving machining tolerances.

- Structural Integrity: The machine’s base is protected from shocks due to ground resonance.

- Easy Installation: The sheets are so easy to cut and adjust that a heavy foundation modification would not be needed.

- Cost Efficiency: Less frequent tool replacement and maintenance costs reduction over time.

- Energy Savings: The power loss caused by the mechanical friction and unnecessary vibration is reduced.

In addition, Unick Insulation Sheets are created with the expectation of having a long lifespan, which means fewer replacements and less discarded materials resulting in a more sustainable and cost-effective operation.

How Better Heat and Vibration Control Improves Your VMC Machine’s Lifespan

The lifespan of a VMC machine is highly dependent on the maintenance of internal alignment and vibration-free cutting. If vibrations are too high, not only will quality be low but also the life of mechanical joints, bearings, and electrical systems will be reduced.

With Unick Insulation Sheets:

- The machines are always running smoothly under the same load.

- Bearings, ball screws, and servo motors are going to be the ones with the least damage.

- After years of use, base alignment is still accurate.

- The operators are going to have more control and confidence in the machining tasks that demand more.

In addition, the system remains cooler, quieter, and more reliable as a result of managing thermal expansion and preventing energy loss through vibration. This means that there will be fewer unplanned repairs and longer service life.

The climate in Haryana, particularly its high summer temperatures, creates thermal stress for industrial equipment. Unick’s insulation design reduces the temperature variations that usually cause distortions in the machine bodies, thus guaranteeing the precision is maintained throughout the year.

Conclusion

In Haryana’s thriving industrial sector, efficiency, and precision stand out as the factors that determine market leadership. The VMC machine owners that decide to upgrade to Unick Insulation Sheets will experience better stability, noise reduction, accuracy improvement, and longer equipment life. The initial investment is quickly recouped through increased production and lower maintenance costs.

A small die shop or a large CNC workshop, whichever you may operate, the selection of Unick Vibration Solutions guarantees that the foundation of every machine will work as hard and as smart as your production team.

With the Unick Insulation Sheets, the trusted solution for vibration-free, heat-resistant, and precision-driven machining, you can upgrade your VMC machine’s foundation today.

Get in touch with Unick Vibration Solutions right away to receive professional advice, installation support at no cost, and recommendations for products that are suitable for the layout of your factory.